China mold manufacturer

Which services can China mold manufacturer spupply ?

China mold manufacturers typically supply services such as plastic injection mold design, mold making, molding, and secondary operations. They can also provide services such as product design and development, prototyping, product and component testing, ultrasonic welding, and more. China mold manufacturer always seeking innovation to make high-quality and precision molds in a wide range of areas, such as automotive parts, medical parts, industrial parts, plastic parts etc. China mold factory can provide a wide range of product solutions for the free 3D drawing, mold design, plastic mold making, injection molding, die casting, machined components and other types of plastic parts manufacturing. We reduicet the production cost by the mold design, mold making, and olastic raw material procurement.

China mold manufacturer have the production equipments as bellow

1. CNC Machining Centers:

2. EDM Machines:

3. Grinding Machines

4. Injection Molding Machines

5. Polishing Machines

6. Drilling Machines

7. Sheet Metal Working Machines

8. Quality Control Equipment

China mold manufacturer production process

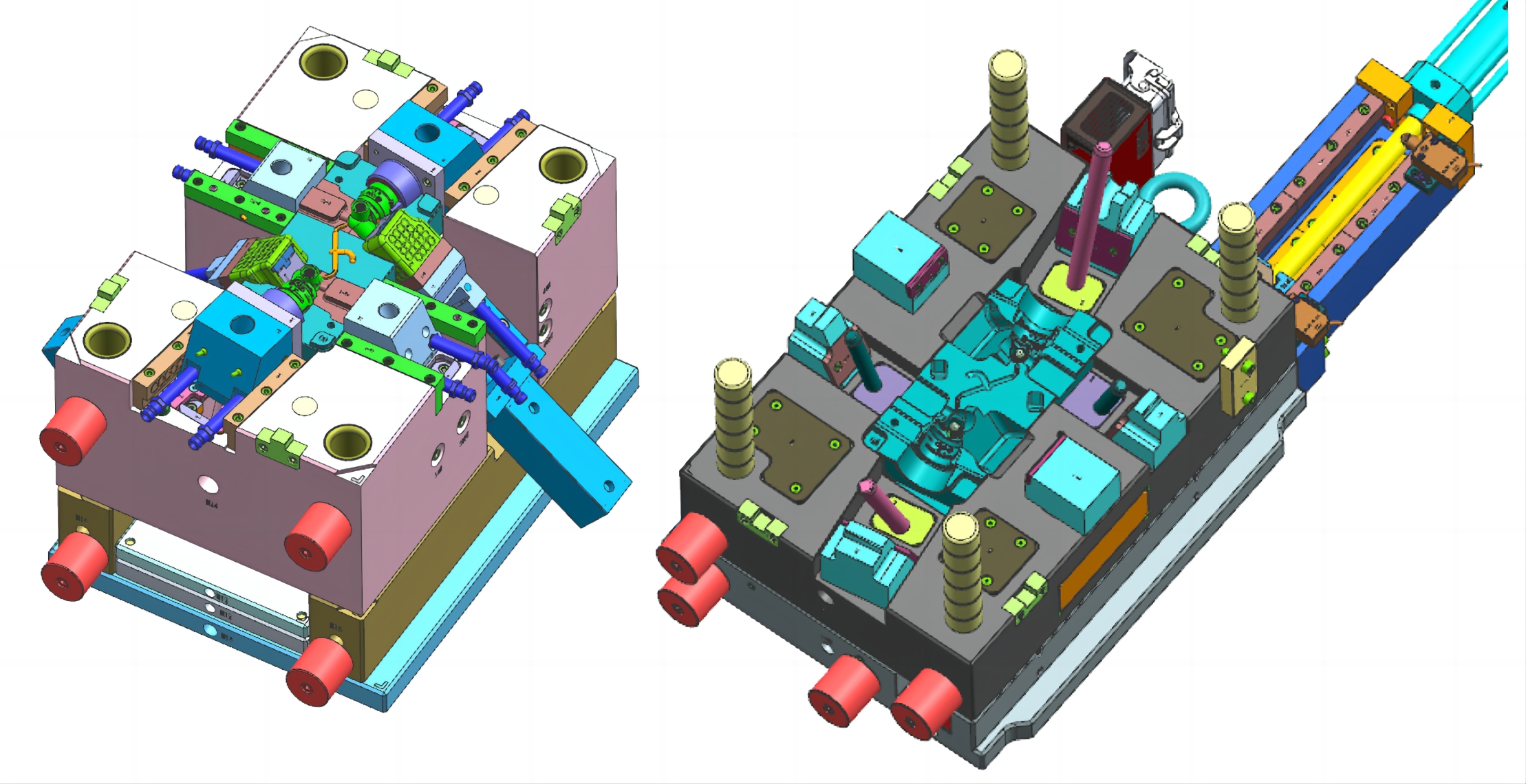

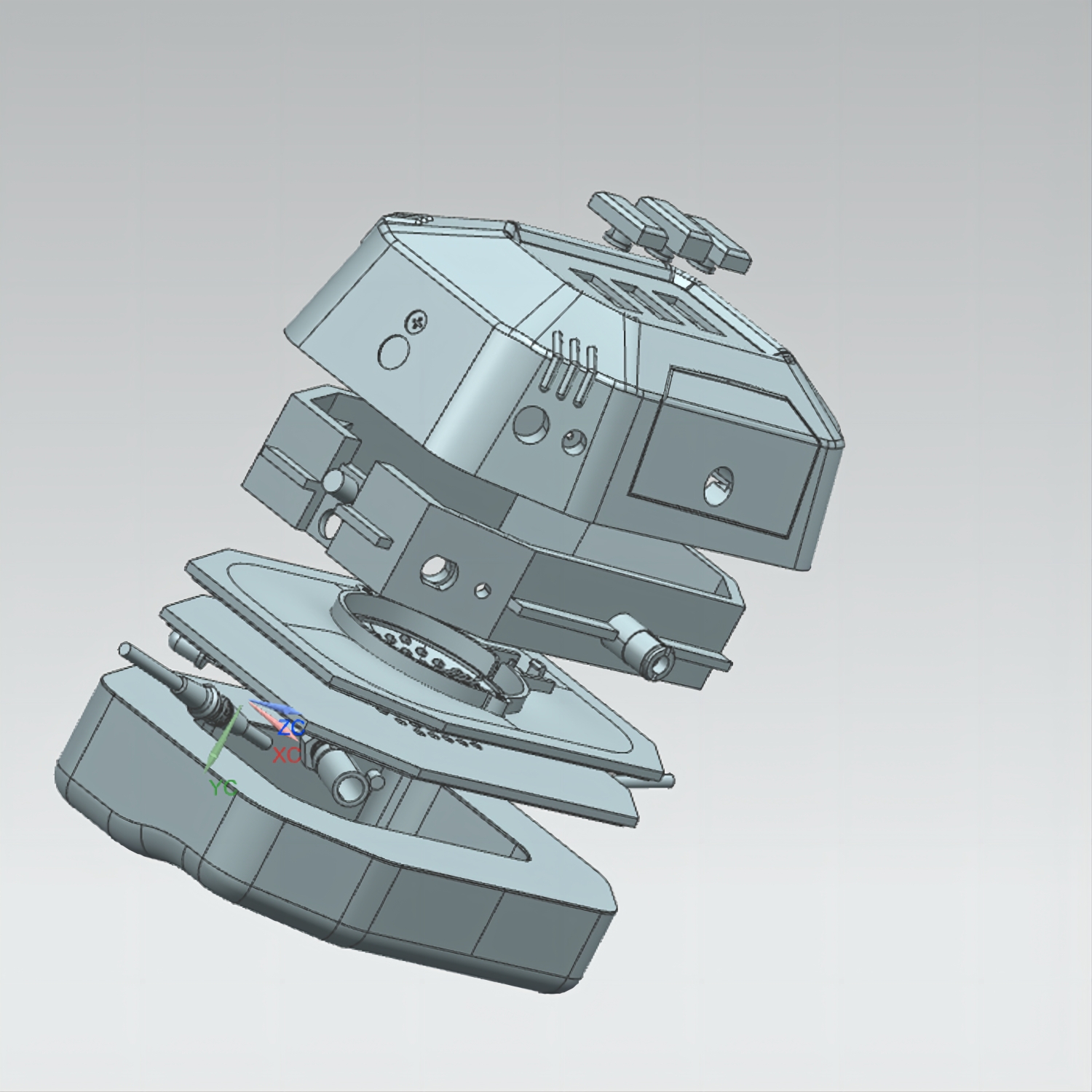

1. Mold design is the first step of the production process is to design the mold according to the customer's product structure and requirements. Mold design is the process of designing molds used to create parts or products through the use of plastic, metal, or ceramic materials. This process involves designing the shape and size of the mold, choosing the best materials for the job, and determining the number of cavities required to produce the desired number of parts or products. Additionally, mold design also includes the selection of suitable molding machines, the selection of suitable injection molding parameters, the selection of suitable cooling systems, and the design of the ejection system. The design of the mold is an important factor in the successful production of parts or products, as it determines the quality of the parts and products produced.

2. CNC machining is a manufacturing process in which pre-programmed computer software controls the movements and operations of a machine. After the design is approved, the plastic mold is machined on special machines, including milling, drilling, grinding, and wire cutting. CNC machining is used to fabricate parts out of metal or other materials by cutting, drilling, grinding, and other methods. CNC machining can be used to produce complex shapes with precision, and can be used to achieve a high degree of accuracy and repeatability. CNC machining is often used for producing prototypes, one-off parts, and small-batch production runs.

3. During the heat treatment process, the plastic mold components are heated and cooled to improve the hardness, strength, and wear resistance of the components. Mold Heat treatment covers those contents: Annealing, Normalizing, Hardening, Tempering, Stress Relieving, Carburizing, Nitriding, Induction Hardening, Age Hardening, Flame Hardening.

4. After heat treatment, the components are assembled according to the design requirements. Mold Assembly covers the assembly and installation of molds and related components, including but not limited to: Mold bases

- Mold plates

- Mold components

- Mold inserts

- Heating elements

- Cooling lines

- Pneumatic lines

- Hydraulic lines

- Lubrication lines

- Electrical wiring

- Programmable logic controllers

5. The surfaces of the mold components are polished to give them a smooth finish. Mold polishing is a process used to finish molds and parts to create a smooth and shiny surface. This process is often used to give parts a more aesthetically pleasing look, improve surface finish, and reduce friction. Mold polishing can be done manually with abrasive materials or through the use of automated grinding and polishing machines. A variety of abrasive materials, such as diamond, ceramic, and aluminum oxide, can be used to achieve different surface finishes.

6. The mold is tested to make sure it meets the customer's specifications and requirements. Mold testing is a process of sampling the air and surfaces to determine the type and quantity of mold present. The samples can be taken from the air, surfaces, or both, depending on what is needed. The results of the testing can help determine if there is a potential health risk from mold, and what steps may need to be taken to address the issue.

What are the advantages of China mold manufacturer compared with German mold factories?

1. Cost Savings: China mold manufacturer offer much lower costs than their German counterparts due to much lower labor and material costs.

2. Faster Turnaround Times: China plastic mold manufacturer can complete projects in a much shorter time frame than German factories, allowing for faster product launches.

3. Greater Flexibility: Chinese mould manufacturer are often more willing to customize molds to fit customer requirements, whereas German mould manufacturers may be more rigid in their approach.

4. Quality Assurance: Chinese mould mold makers must adhere to strict quality control standards, ensuring that their products meet customer expectations.

5. Access to the Latest Technologies: Chinese mould makers often have access to the latest technologies, allowing them to produce high-quality molds quickly and efficiently.

Equipments that China mold industry can produce independently

1. Injection Molding Machines: High-precision injection molding machines are the most important tool for plastic mold injection. China has made great progress in the development and manufacture of injection molding machines in recent years, and has become one of the leading producers and exporters in the world.

2. CNC Machines: Computer Numerical Control (CNC) machines are commonly used in mold production. China is a major producer of CNC machines and is capable of manufacturing high-precision CNC machines for mold production.

3. EDM Machines: Electrical Discharge Machining (EDM) machines are used to cut and shape molds. China has been making great strides in EDM technology and is capable of producing EDM machines for mold production.

4. Die Casting Machines: Die casting machines are used to produce precision metal parts and components. China is a major producer of die casting machines, and is capable of manufacturing machines for the production of molds.

5. 3D Printers: 3D printers are used to produce complex shapes and components with a high degree of accuracy. China is a leading producer of 3D printers and is capable of manufacturing 3D printers for use in mold production.

What is the service level and product quality of China mold manufacturer?

The service level and product quality of China mould manufacturers can vary greatly. Some of the top manufacturers offer world-class customer service, high-quality products, and competitive prices. However, there are also some manufacturers with less-than-optimal customer service, inferior product quality, and higher prices. It is important to research the specific manufacturer to ensure you are getting the best service level and product quality for your needs.

Matters needing attention when cooperating with China mold factory

1. Quality is the life of a mold factory. Make sure to check the quality of the molds before you make a purchase.

2. Price negotiation is a common practice in China, so be sure to negotiate the price with the mold factory to make sure you get the best deal.

3. Make sure to ask the mold factory about their delivery time and ensure that they can meet your requirements.

4. Communication is key when working with a China mold factory. Make sure to keep in touch with them regularly to stay up to date with their progress.

5. Make sure to ask the mold factory for after-sale service. This is important in case something goes wrong and you need to get the mold fixed or replaced.

What is the international level of independent design capabilities of China mold manufacturer? What are the advantages and disadvantages compared with Germany?

China mold manufacturers have an international level of independent design capabilities. China has some of the most advanced and comprehensive design and manufacturing capabilities for molds in the world. The Chinese mold industry has an extensive range of products and services, from design, engineering, mold making, prototyping, testing, injection molding and 3D printing, to sophisticated and complex high precision molds. China’s mold industry is also highly competitive, with many companies offering competitive pricing, as well as high-quality and timely service. With their advanced technology and competitive cost, China’s mold manufacturers have been able to expand their international presence in the mold industry.

The advantages of China's mold manufacturers compared to Germany are mainly in terms of cost, technology and speed. Chinese mold manufacturers can deliver molds at a much lower cost than their German counterparts, which helps reduce the cost of production. Additionally, Chinese mold makers possess advanced technologies and can create more complex molds, including high-precision molds, in a much shorter amount of time. This helps to reduce lead times and increase the efficiency of production.

The disadvantages of China's mold manufacturers compared to Germany are mainly due to the lack of experience and knowledge in the industry. German mold makers are more experienced and knowledgeable in terms of design, engineering, and production. Additionally, German mold makers use higher-quality materials for their molds, which can result in better performance and longer lifespans. Finally, the overall quality of the molds produced in Germany is higher than those produced in China.

Overview of international patents in China mold industry

International patents in the Chinese mold industry cover a wide range of areas, including but not limited to mold design, mold manufacturing, plastic injection mold, mold die casting, mold surface treatment, and mold maintenance. In terms of mold design, Chinese companies have developed several patent technologies, such as a patent for a new type of mold structure, a mold-making method, and a mold-making device. In terms of mold manufacturing, Chinese companies have developed a patent for a die-casting mold with a high-precision and large-scale, a new type of mold manufacturing process, and a mold manufacturing system. In terms of injection mold, Chinese companies have developed a patent for an injection molding device, a die-casting mold with a high-precision and large-scale, and a die-casting process. In terms of mold die casting, Chinese companies have developed a patent for a die-casting process and a die-casting device. In terms of mold surface treatment, Chinese companies have developed a patent for a method for treating the surface of a mold and a device for treating the surface of a mold. Finally, in terms of mold maintenance, Chinese companies have developed a patent for a mold maintenance system.

Our Certificates

By co-operating with Elite Mold, you have selected one of the most reliable ISO 9001 certified plastic mold manufacturer, Elite Mold as a plastic injection mold manufacturer specializing in plastic injection mold and supplying plastic injection molding services for plastic mold design, prototype makings, mold flow analysis, precise machining, OEM services, ODM services and so on, building custom plastic injection molding. We are committed to enhance the Process optimized and quality of service, shorten lead time and assist in lowering inventory, by providing new products every year to bring in continuous and higher profits for our clients. The ability to produce mold at the International standard, strong engineering and mold design capability, aggressive delivery, competitive pricing and business integrity continues to be the success factor of Elite Mold.